CNT Composite

The coating is inorganic, 3-5 um thick, and exhibits the following properties:

- Light absorption is compliant with state-of-art earth observation requirements in the visible and IR

- Light reflection behavior is Lambertian

- Various materials and shapes can be coated

- The coating features a good adhesion and outgassing behaviors

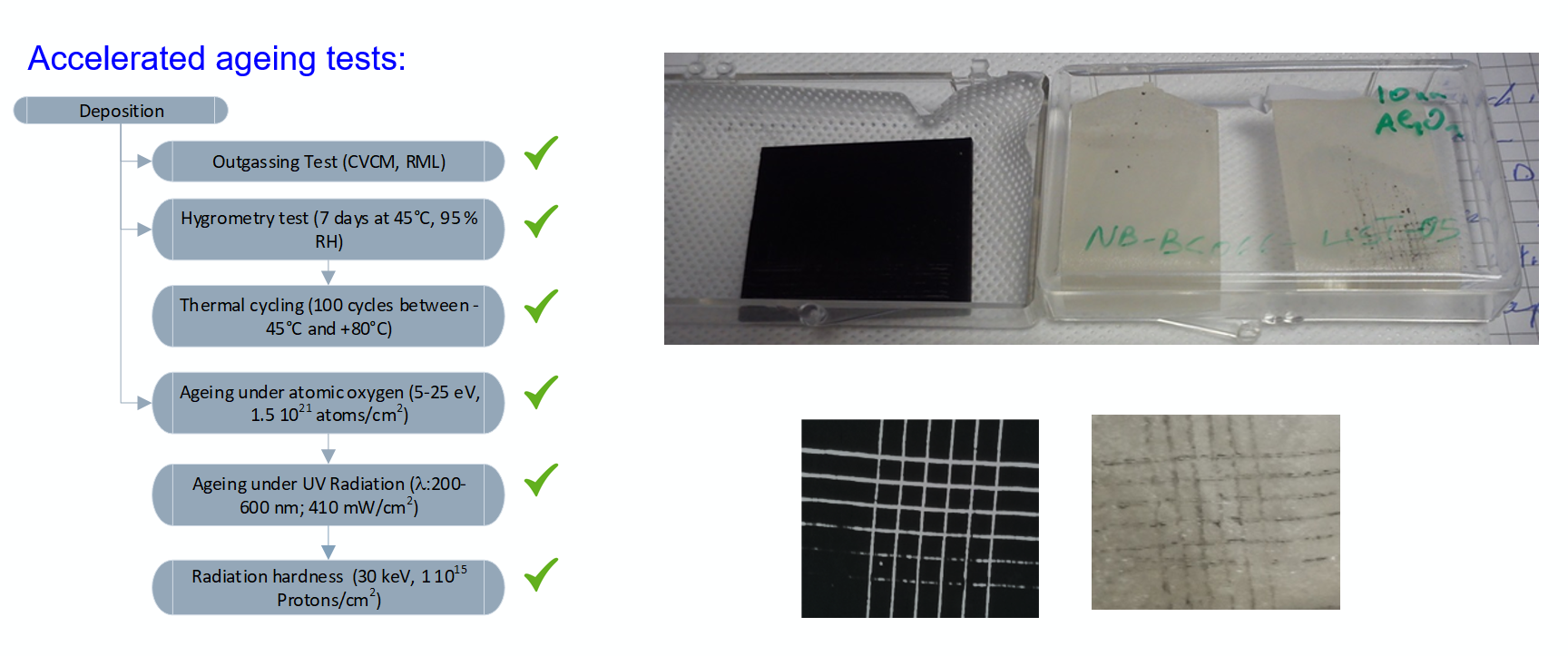

- Marginal effect was noticed after accelerated ageing tests (ATOX, UV, ionizing radiations)

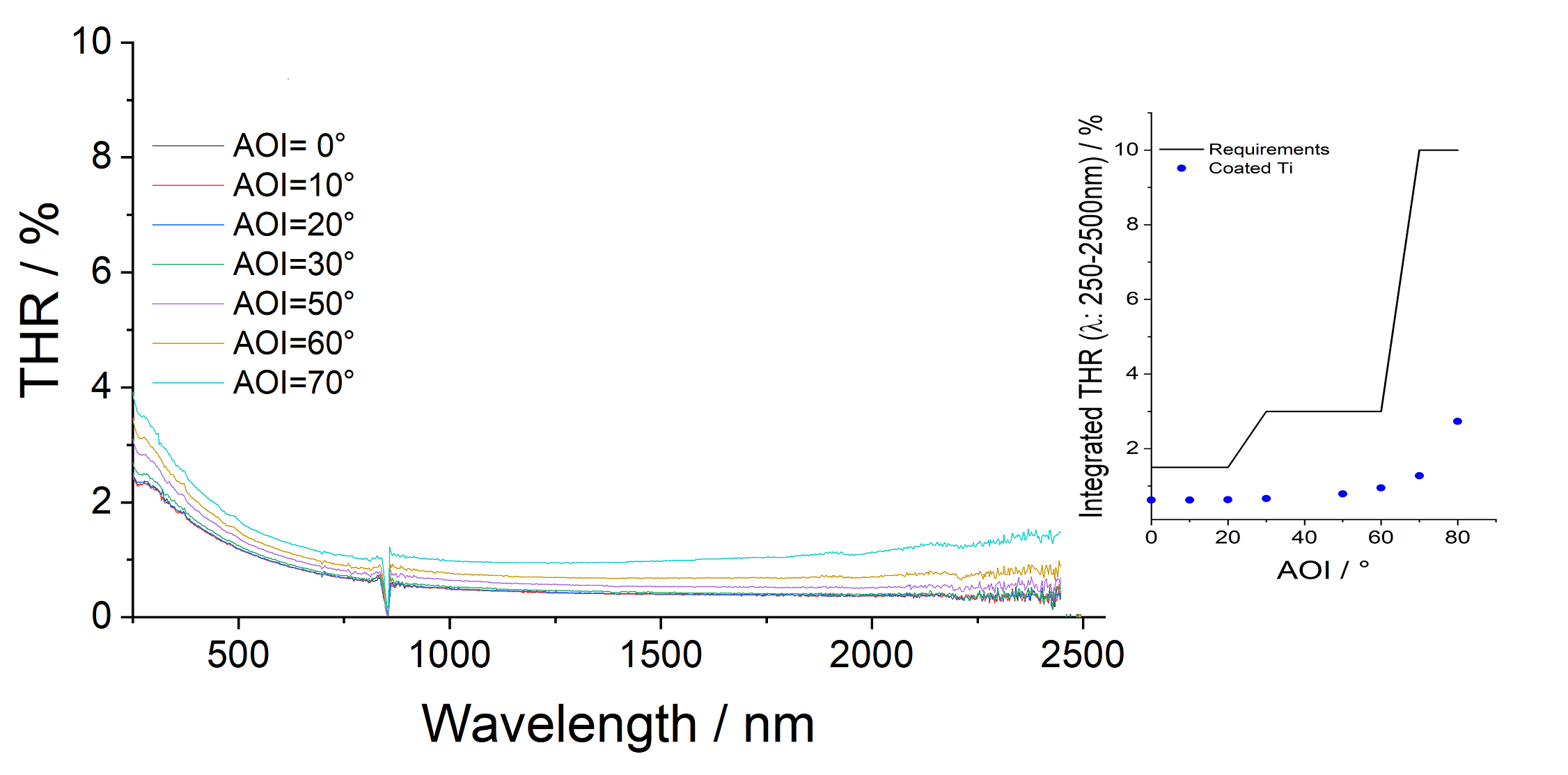

UV-vis-NIR: The CNT-based coating features a total hemispherical reflection (THR) that decreases with the wavelength to reach a plateau in the NIR. The integrated THR in the 250-2500nm spectral range is ~0.6% at normal incidence; and remains <1.3% even at grazing incidence (AOI=70).

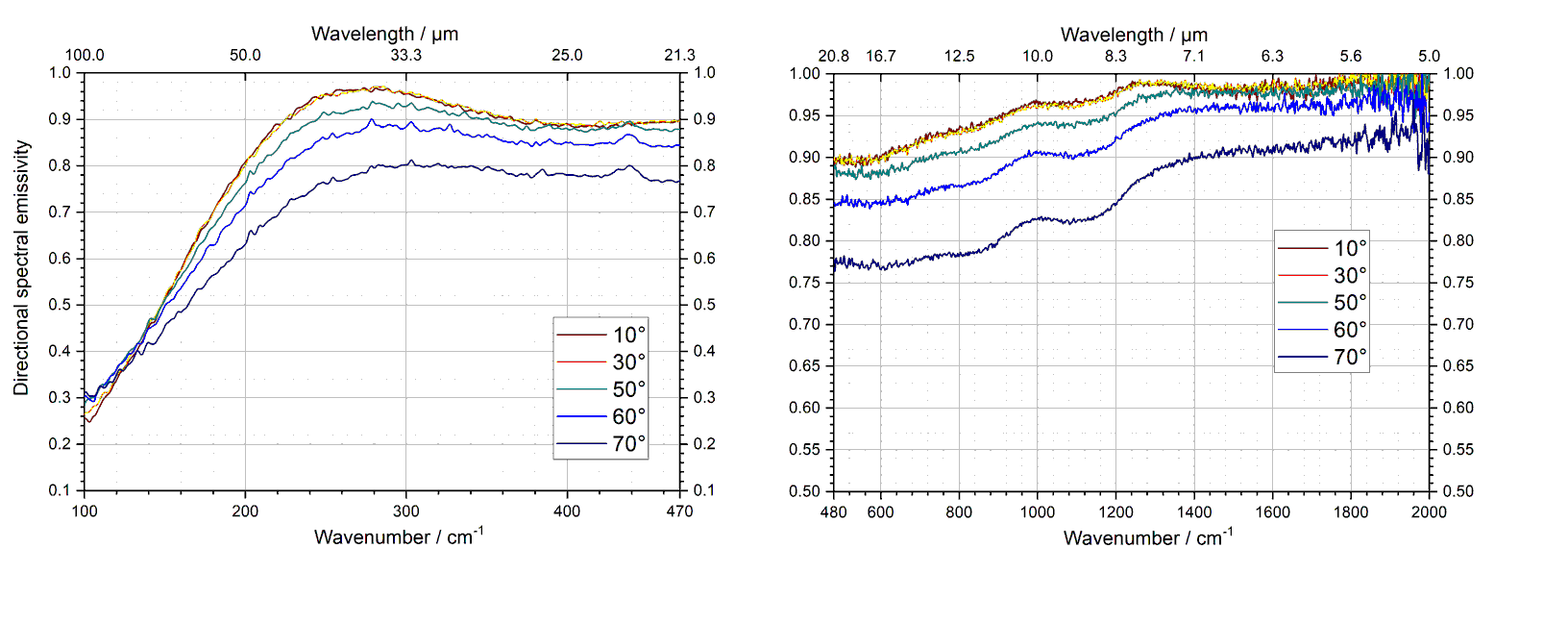

MIR and FIR: The measured directional spectral emissivity is above 0.95 up to wavelengths exceeding 8 um. The dependency on the wavelength and on the angle of incidence (≤60°). The overall emissivity remains high up to up to wavelengths exceeding 40 um.

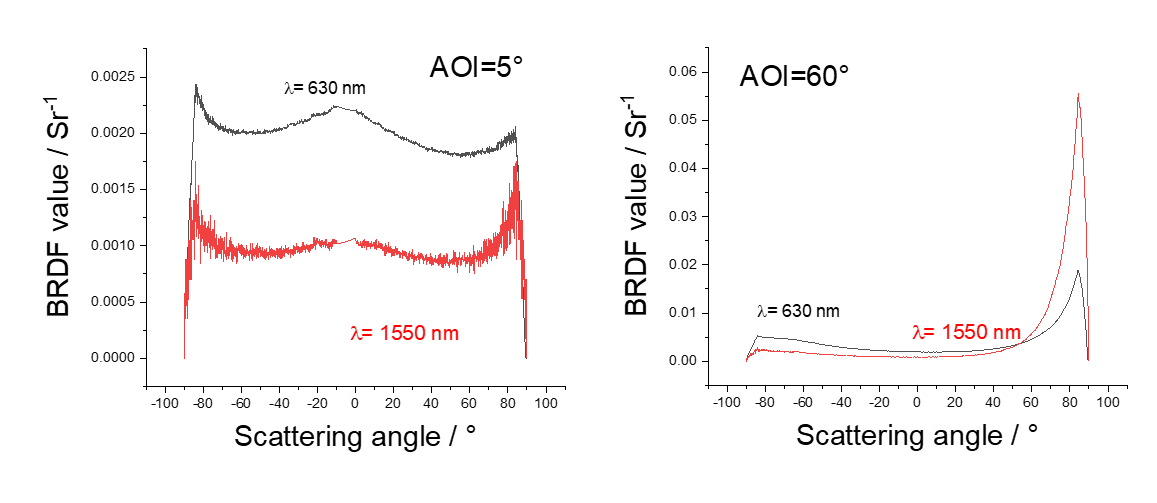

BRDF: The bidirectional reflectance distribution function reveals a Lambertian behavior. A flat profile is obtained at near normal incidence, whereas slight forward scattering is observed at grazing incidence.

Versatility: The super black coating is 3-5 um thick and can be applied on various materials including glass, ceramic, aluminum, and titanium. 3D-shapes made by top-down (e.g. machining) or bottom-up (additive manufacturing) process can be coated.

Properties: The coating complies with the adhesion tape test with the 3M-250( 8N/cm) and the outgassing test reveals the following characteristics: TML (0.007 %); CVCM (0.009 %); WVR (0.003 %) and RML (0.004 %).

Ageing: Marginal impact was noticed after the accelerated ageing test series.